Connected Machines in the Manufacturing Industry

How to digitalize your shopfloor successfully

Connecting Machines offers enormous advantages for your company: The transparency you create in the production enables more efficient management and additional services for your customers. The IoT capability of a product paves the way for new value-added services and revenue increases. Many different connection standards, secure IT/OT communication (Internet of Things/Operational Technology), and integration into existing processes and reporting represent a significant challenge in practice. With our partner TTTech Industrial in the field of Industrial Internet of Things (IIoT) and a strong partner network for hardware and device management, we can provide you comprehensive support and advice for the introduction or even optimization of Connected Machines.

Advantages of Connected Machines for You as a Manufacturing Company

Increase transparency

The key to responding to a volatile environment is transparency - the comprehensive and transparent insight into your production. Through connected machines, we make this visible and thus controllable.

Improve efficiency

Machine data helps you become more efficient: For example, through automated replenishment, production planning, or predictive models using AI (Artificial Intelligence).

Boost production quality

Connected Machines themselves check the completeness of work steps or the correct production flow. In this way, you close the gap between planning and reality.

Raise the level of automation

The better machines are integrated, the more options arise. For example, automated quality control or the creation of Digital Twins.

Enabling new business models

In addition to connecting your own machines, your products can also be delivered to customers IoT-enabled. The basis for new sales and additional services.

Offer new value-added services

Use the data you receive about the machines you sell, which can be analyzed through machine connectivity, to learn and develop new services for your customers.

The Path To Industry 4.0 - The Edge Management System

As part of the LNI testbed "Edge Management", use cases for the manufacturer-independent management of edge devices via a management system are being tested. The aim is to network devices across manufacturers and provide impetus for the development of innovative standards. Possible solutions are jointly developed and tested in plugfests. As a partner of LNI 4.0, Arvato Systems has taken on the patronage of the testbed.

As a result of the collaboration within the testbed, the LNI 4.0 Edge Management Demonstrator was developed, which represents a first prototypical, industrial breakthrough across manufacturer boundaries.

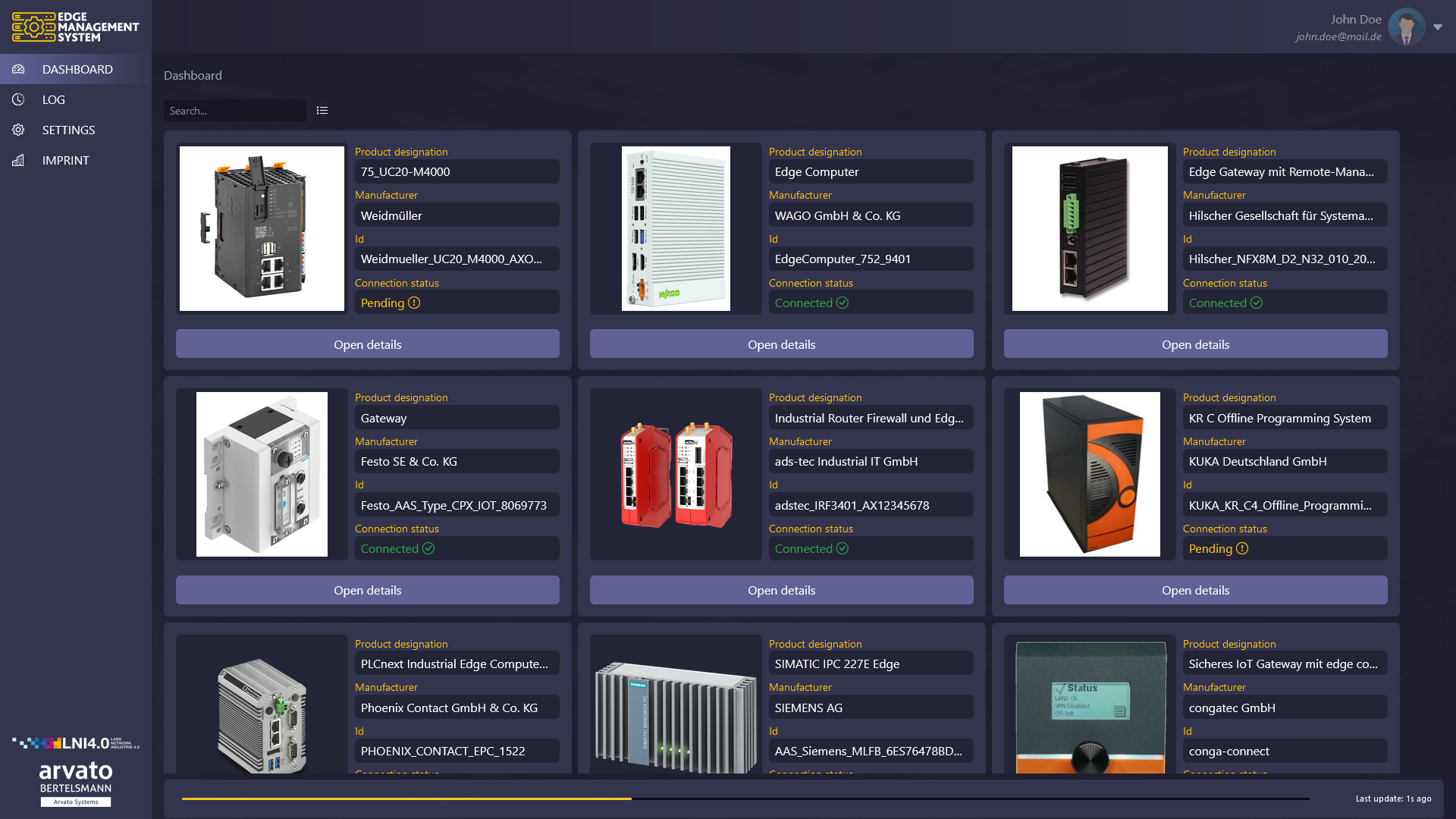

Dashboard

Dashboard of the Edge Management System as an overview of the various devices from different manufacturers

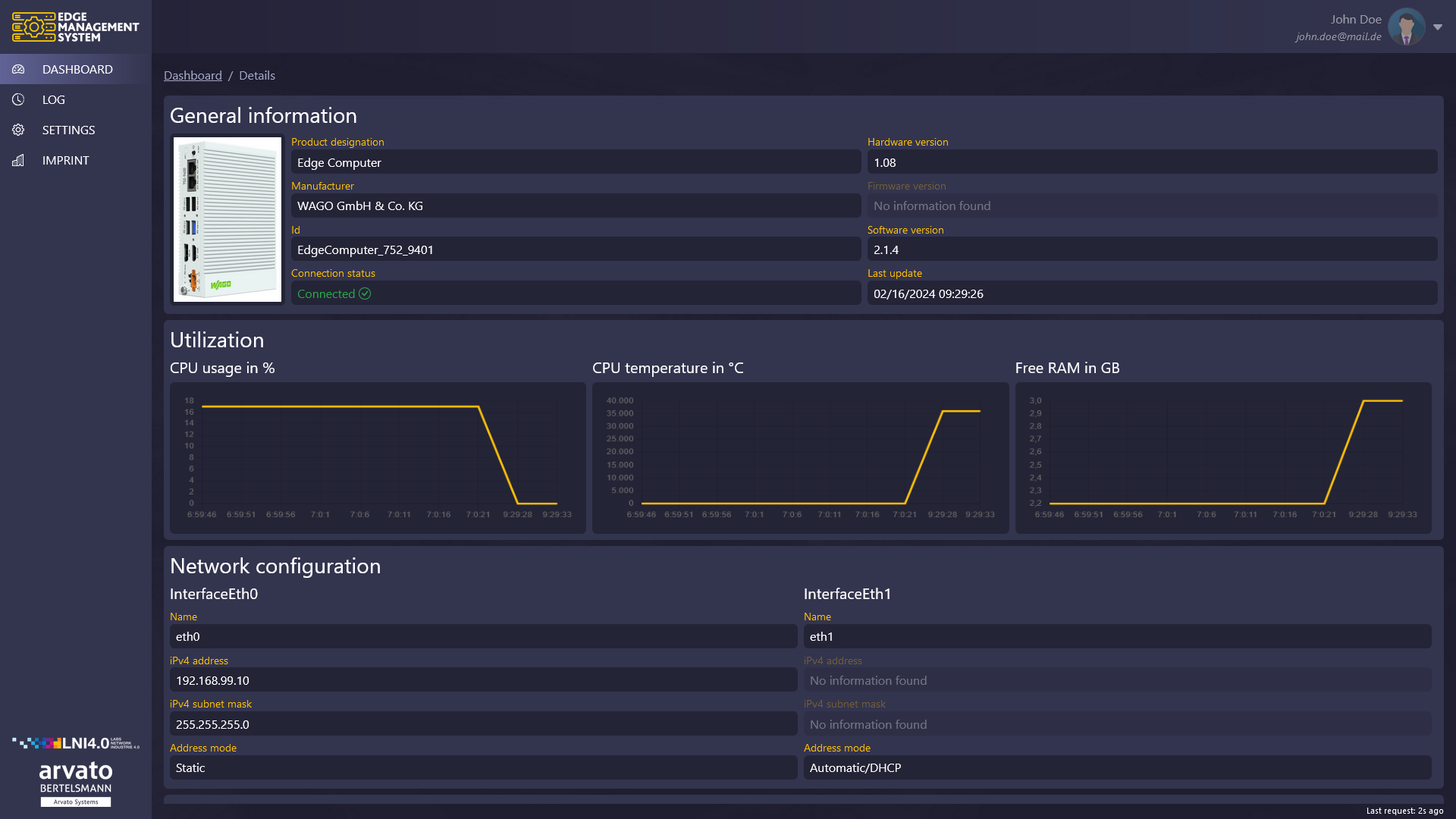

User Interface

User interface - overview of an individually selected device for various information, such as CPU utilization, temperature and firmware

Our Services for Your Success

Frequently asked questions about machine connectivity in the manufacturing industry

-

What is the goal of machine connectivity?

-

How to optimize machine connectivity in times of networked processes?

-

Does a machine connectivity solution intervene directly in the production process or the daily operation of the machines?

-

How is it ensured that the integration of sensors and machine monitoring software does not have a negative impact on production or other IT systems?

-

What long-term cost savings can manufacturing companies expect by using machine connectivity and how can the return on investment (ROI) be calculated?

Your Contact for the Manufacturing Industry