Connected Machines in the Manufacturing Industry

How to digitalize your shopfloor successfully

Connecting Machines offers enormous advantages for your company: The transparency you create in the production enables more efficient management and additional services for your customers. The IoT capability of a product paves the way for new value-added services and revenue increases. Many different connection standards, secure IT/OT communication (Internet of Things/Operational Technology), and integration into existing processes and reporting represent a significant challenge in practice. With our partner TTTech Industrial in the field of Industrial Internet of Things (IIoT) and a strong partner network for hardware and device management, we can provide you comprehensive support and advice for the introduction or even optimization of Connected Machines.

Advantages of Connected Machines for You as a Manufacturing Company

Increase transparency

The key to responding to a volatile environment is transparency - the comprehensive and transparent insight into your production. Through connected machines, we make this visible and thus controllable.

Improve efficiency

Machine data helps you become more efficient: For example, through automated replenishment, production planning, or predictive models using AI (Artificial Intelligence).

Boost production quality

Connected Machines themselves check the completeness of work steps or the correct production flow. In this way, you close the gap between planning and reality.

Raise the level of automation

The better machines are integrated, the more options arise. For example, automated quality control or the creation of Digital Twins.

Enabling new business models

In addition to connecting your own machines, your products can also be delivered to customers IoT-enabled. The basis for new sales and additional services.

Offer new value-added services

Use the data you receive about the machines you sell, which can be analyzed through machine connectivity, to learn and develop new services for your customers.

The Path To Industry 4.0 - The Edge Management System

As part of the LNI testbed "Edge Management", use cases for the manufacturer-independent management of edge devices via a management system are being tested. The aim is to network devices across manufacturers and provide impetus for the development of innovative standards. Possible solutions are jointly developed and tested in plugfests. As a partner of LNI 4.0, Arvato Systems has taken on the patronage of the testbed.

As a result of the collaboration within the testbed, the LNI 4.0 Edge Management Demonstrator was developed, which represents a first prototypical, industrial breakthrough across manufacturer boundaries.

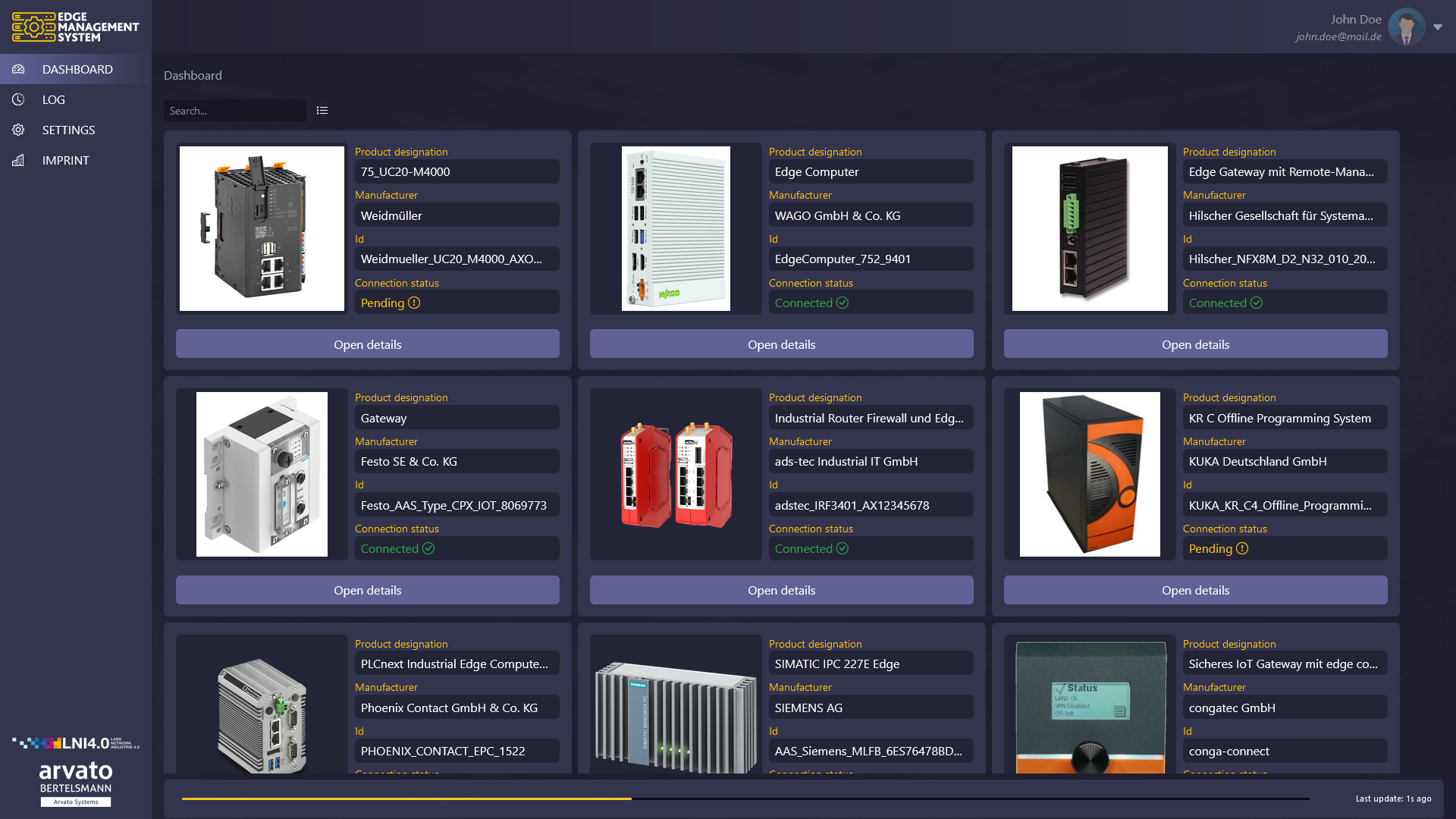

Dashboard

Dashboard of the Edge Management System as an overview of the various devices from different manufacturers

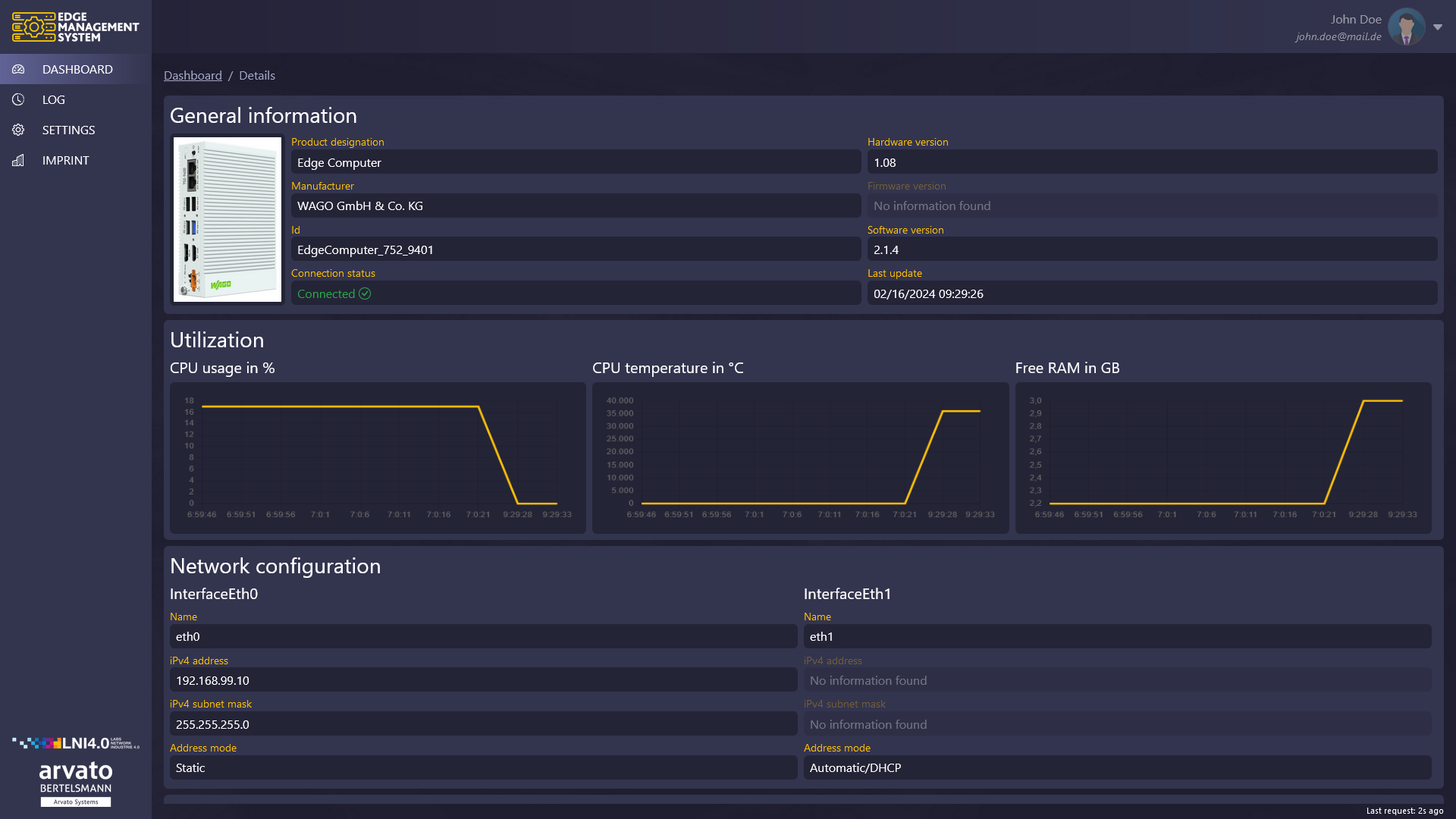

User Interface

User interface - overview of an individually selected device for various information, such as CPU utilization, temperature and firmware

Our Services for Your Success

-

Implementation of a holistic strategy as the key to success

We bundle the competence from strategy finding to the operation of your solution. We provide you with a broad portfolio, from setting up the right IT infrastructure to integration and modern data management. At the same time, we support you in connecting Machines and utilizing the data gained and advise you on new, revenue-generating business models and services.

-

Holistic solution from a single source - enhanced by the best solutions on the market

We can do many things, but not everything. That's why we specifically complement our solutions and services with those of market-leading companies from our strong partner network. Our target is to create an optimal and individual solution for you. We are your central point of contact and will guide you fairly, solution-oriented, and at eye level. For you, this means reduced risk, clear project responsibilities, and the certainty of receiving a modern and future-proof solution.

-

We accompany you holistically - from the vision to successful operation

We accompany you not only with the vision but go the entire way with you: From the first solution sketch about the implementation to the successful use in your company. Even beyond that, we are at your side. In doing so, we are committed to finding practical, implementable, and cost-effective solutions that we advocate with conviction.

Frequently asked questions about machine connectivity in the manufacturing industry

-

What is the goal of machine connectivity?

The aim of machine connectivity is to seamlessly integrate production machines and systems in the manufacturing industry seamlessly into networked processes. This should improve efficiency, productivity and data transparency. Specifically, it is about:

Automation: Machines should be able to automatically transmit data on their status, operating parameters and production progress.

Real-time monitoring: The connection allows you to monitor machines in real time in order to identify and rectify potential problems at an early stage.

Data analysis: The data collected enables production processes to be analyzed in order to identify bottlenecks, improve quality and predict maintenance requirements.

Flexibility: Networked machines can react and adapt flexibly to changes in production.

Cost savings: More efficient processes and predictive maintenance can lead to cost savings.

Overall, machine connectivity aims to optimize the production landscape and increase competitiveness

-

How to optimize machine connectivity in times of networked processes?

In times of networked processes, optimal machine connectivity is crucial for efficiency and productivity in the manufacturing industry. Here are some proven approaches:

Standardized interfaces: Use standardized communication protocols such as OPC UA, MQTT or RESTful APIs to connect machines with other systems. These protocols enable seamless integration and interoperability.

Edge computing: Use edge devices to process data directly on the machine. This allows you to reduce latency and improve response time.

Security: Implement robust security measures to protect the machine connection from cyber attacks. This includes authentication, encryption and access controls.

Dataanalysis: Collect data from the machines and analyze it to gain insights. This can help predict maintenance needs, optimize production processes and quality control.

Scalability: Plan the machine connection in such a way that it is scalable and can keep pace with the growth of your company.

Remember that the optimal machine connection depends on the specific requirements of your company. It is advisable to work with an expert to find the best solutions.

-

Does a machine connectivity solution intervene directly in the production process or the daily operation of the machines?

The machine connectivity solution can intervene both in the production process and in the daily operation of the machines. Here are some aspects:

Production process: The machine connection enables real-time monitoring and control of machines during production. It can provide data on production progress, quality and efficiency. If necessary, automatic adjustments can be made to avoid bottlenecks or optimize production performance.

Daily operation: In daily operation, the connection enables the remote monitoring of machines. Operators can monitor the condition of the machines, identify maintenance requirements and take action if necessary. This can improve the availability and service life of the machines.

Overall, the degree of intervention depends on the specific implementation and the company's objectives.

-

How is it ensured that the integration of sensors and machine monitoring software does not have a negative impact on production or other IT systems?

Ensuring that the integration of sensors and machine monitoring software does not have a negative impact on production or other IT systems requires careful planning and implementation. Here are some best practices:

Pilot projects and tests: Start with pilot projects to test the integration on a limited scale. Monitor the impact on production and other systems and adjust the solution as needed.

Isolation: Isolate the sensors and monitoring software from critical production processes. Use separate networks or VLANs to minimize potential interference.

Redundancy and fallbacks: Implement redundancy mechanisms to avoid failures. Make sure there is a fallback mechanism in case the monitoring software fails.

Security: Protect the sensors and monitoring software from unauthorized access. Use strong authentication and encryption.

Documentationand training: Document the integration in detail and train employees to recognize and resolve potential problems.

Remember that every implementation is unique and it is advisable to work with experts to consider the specific requirements of your business.

-

What long-term cost savings can manufacturing companies expect by using machine connectivity and how can the return on investment (ROI) be calculated?

Manufacturing companies can expect a range of long-term cost savings from using machine connectivity, including:

Increased efficiency: Machine connectivity can increase the efficiency of manufacturing processes by automating tasks, reducing errors, and improving data transparency. This can lead to shorter production times, lower scrap rates, and higher productivity.

Lower operating costs: Automating tasks through machine connectivity can reduce the need for labor, resulting in lower labor costs. In addition, improved data transparency can help reduce energy consumption and material waste.

Improved quality: Machine connectivity can improve the quality of manufactured products through more precise control and monitoring of processes. This can lead to lower warranty costs and higher customer satisfaction.

Increased flexibility: Machine connectivity can increase the flexibility of manufacturing companies by easily adapting production processes to new products or requirements. This can lead to a faster time to market and a more competitive advantage.

The return on investment (ROI) of machine connectivity can be calculated by calculating the following metrics:

Net Present Value (NPV ): The NPV is the sum of the discounted future cash flows of a project less the initial investment costs.

Internal rate of return (IRR): The IRR is the discount rate at which the NPV of a project equals zero.

Payback period: The payback period is the period required to cover a project's initial investment costs with future cash flows.

Calculating the ROI of machine connectivity can be complex and requires consideration of a number of factors, such as the cost of the investment, the expected savings, the life of the equipment and the discount rate. It is important to create a detailed business plan and carefully evaluate the financial impact of machine connectivity before making an investment.

There are several resources that can help manufacturing companies calculate the ROI of machine connectivity. In addition, it is important to note that the benefits of machine connectivity are not just financial. Automating tasks can also improve morale and employee satisfaction by freeing workers from tedious and repetitive tasks and allowing them to focus on more important tasks. Overall, machine connectivity can be a valuable investment for manufacturing companies that can lead to long-term cost savings, improved quality, and increased flexibility.

Your Contact for the Manufacturing Industry